What is a half-cell module?

The conventional full-cell panel (60 units) is made of 60 or 72 units on the entire panel. The semi-battery module increases double the number of batteries of each panel to 120 or 144 battery cells. The size of the panel is the same as the size of the full unit panel, but the number of cells is doubled. By double the number of batteries, the technique creates more pathways to capture energy in the sun and send them into the inverter.

Essentially, the semi-battery technology is to cut the battery in two halves and reduce the resistance, so that efficiency can be improved. Traditional full-cell panels with 60 or 72 batteries generate resistors, which reduces the ability of the panel to produce more power. The semi-battery having 120 or 144 batteries has a lower resistance, which means capturing and producing more energy. The semi-battery panel has a smaller battery on each panel, which reduces the mechanical stress on the panel. The smaller the hole, the smaller the chance of the panel microcrack.

In addition, semi-battery technology provides higher power output rated values and is usually more reliable than conventional full-cell panels.

(full-cells) (half-cells)

Why use HALF-CELL technology when installed next time?

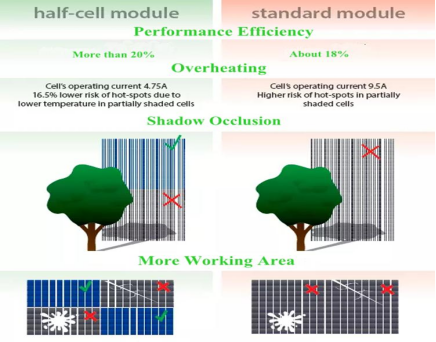

In any roof photovoltaic system sales, it is most important to provide customers with more power and save funds. HALF-Cell technology allows your solar installation to make a better place. Over the years, the increase in the penetration rate of semi-battery is attributed to some very obvious advantages, such as: Excellent performance under low light conditions The semi-battery technology is very good under weak light conditions. This is due to the reason for the design, the increase in the number of battery cells provides more power to the inverter.

Half battery technology is more durable, long service life

Because the size of the solar cell is small, HALF-Cell technology is less susceptible to microcracks. Reduces the mechanical stress on the entire panel, which reduces the opportunity to produce microcracks. Therefore, the Half-Cell panel is more durable, and it is not easy to rupture for a long time. Better in high temperature conditions It turns out that the semi-battery technology is good in high temperature conditions. As we all know, Australia has never encountered hot weather conditions. This is the increasingly popular reason for Half-Cell technology in the Australian Asia-Pacific market. The semi-battery technology is not easy to show the panel failure. Split junction box Hotspots are very common in the improper manufacturing solar PV panel and will severely reduce the life of the solar PV panel. The heat content of the half-cell solar photovoltaic battery panel is lower than a single battery on the battery board. Hotspots are common, and the negative impact produced by the solar photovoltaic system is that they will absorb a large amount of constant heat. In some main circumstances, hotspots may cause fire hazards to customers' homes. Use a split junction box to reduce battery heating and a hot spot may occur.

(East Lux 440W-455W Newly Half-Cell)

Newly launched Excellent Half-Cell products

East Lux Energy launched a new series of 60 Half-Cell solar panels, which have 182 mm wafer, up to 21% efficiency,Bifacial PERC cell technology.

We have 25 years of product warranty,Excellent performance, even in cloudy days, high power output,Durable design.

We are very happy to see the explosive growth of the market.To learn more, welcome to contact us: Sales@eastluxenergy.com